Use cases

Accelerate innovation with unlimited access to Spiro Control services and high-performance products.

Use cases

Accelerate innovation with unlimited access to Spiro Control services and high-performance products.

IMPROVE YIELD AND REDUCE WASTE IN FEEDSTOCK, ENERGY AND FACILITY TIME

Chemicals

Using Spiro Control applications, chemicals manufacturers can respond to customer needs efficiently and maximise the yield of their most valuable products. Our competence and know-how in chemical unit operations makes us an ideal partner for improving operations.

ACHIEVE OPERATIONAL EXCELLENCE

Food & Beverages

Using Spiro Control applications, food and beverage manufacturers can run plant operations in a much more stable manner, with fewer equipment failures, extended time between cleaning of equipment and, ultimately, less downtime. Our strength lies in increasing the reliability of continuous operations that are run in extreme conditions.

IMPROVE ENERGY PERFORMANCE, REDUCE COSTS

Pulp & Paper

There are a number of energy-hungry unit processes involved in pulp and paper production. Tightening regulations, increasing energy costs and growing competition all combine to increase the need for better control of these units. As well as reducing energy consumption, our solutions can help you increase production rates, and improve stability.

INCREASE BIOMASS CONVERSION TARGET

Anaerobic Digestion

Use operational data to improve performance and keep the plant running close to its optimum capacity under all conditions. Spiro Control applications can model the mass and energy balances to rate the thermal and hydraulic performance of the process.

INCREASE EFFICIENCY WITHOUT INVESTING IN NEW CAPITAL

Oil & Gas

No matter the scale of the operation, our all-in-one cost-effective solutions can deliver benefits measured in terms of increased process reliability that far exceed total project costs.

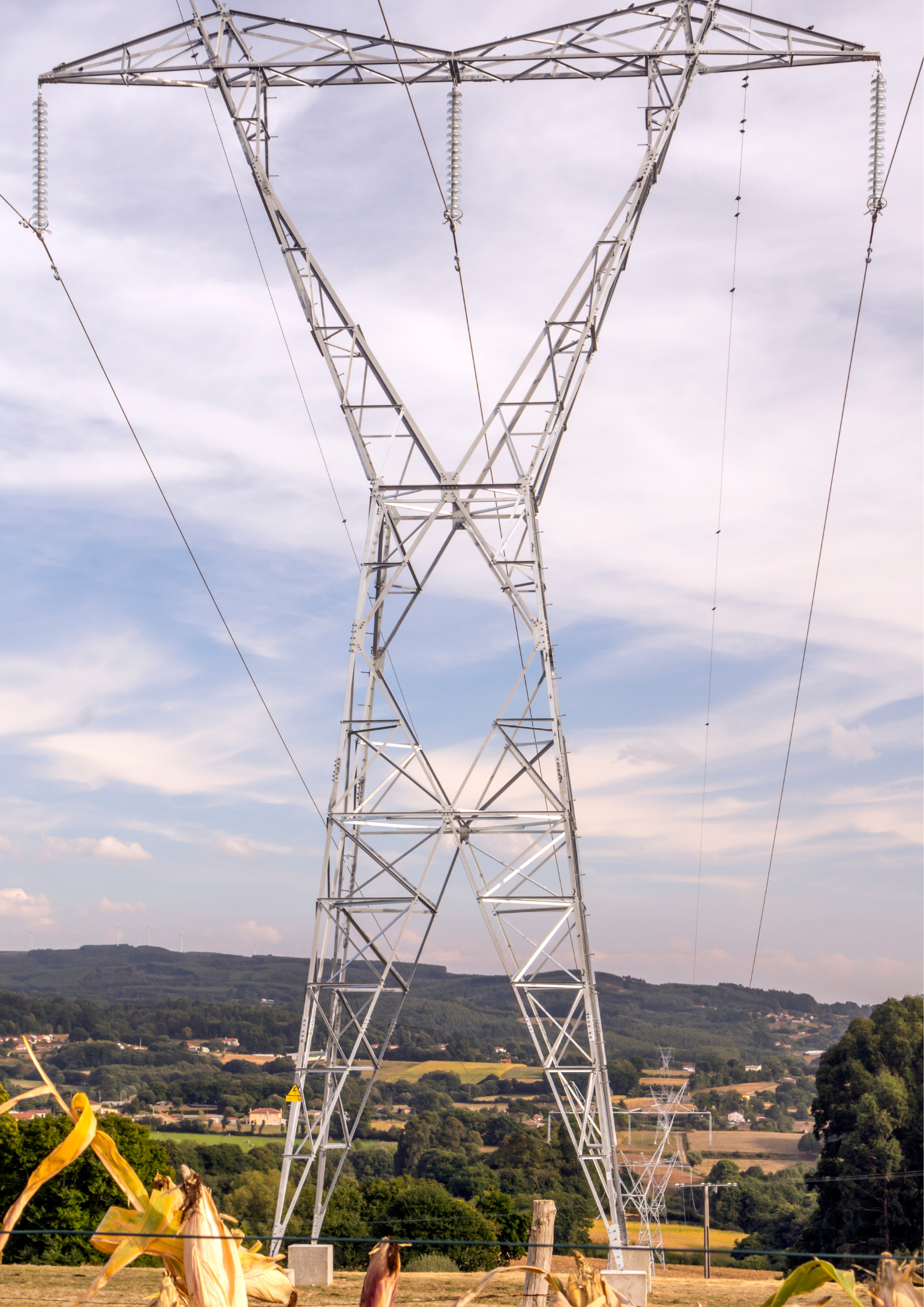

OPTIMISE RESPONSIVENESS TO DYNAMIC MARKET DEMAND

Renewable Energy

Changing weather conditions present major challenges for predicting and delivering a reliable supply of electricity. Spiro Control applications enable real-time adjustments to maximise power generation and provide advanced analytics for accurate energy forecasting and delivery.

REDUCE OPERATOR STRESS

Mining, Minerals & Metals

The challenge of controlling complex mining processes is compounded by the scarcity of qualified and experienced operational personnel. Spiro Control applications can help ease the stress on operating staff by automating responses to process disturbances. Example use cases include stabilising grinding circuit operation and flotation circuits operation to improve energy consumption and throughput.

ADAPTIVE ON-LINE MOISTURE CONTROL OF FLASH DRYING PROCESS

Flash Dryers

The benefits of applying a model based predictive control strategy on a flash drying process include increased throughput, faster start-up and tighter product specification.

ENERGY DEMAND MANAGEMENT

Utilities

Using modelling techniques and real-time data analytics, we can aggregate the interests of users, creating the possibility of bidding into the energy market and selling or buying extra energy at critical moments. By effectively managing supply and demand of energy, performance can be optimised and costs minimised.

BOOST PERFORMANCE

Power Generation

Reducing the volatility of a power generation process means it can be operated closer to the plant’s economic optimum point. Rather than operating within a comfort zone, you can run at the limits of a process without risk of violating constraints. An example use case is combustion optimisation. Spiro Control applications can manage the optimum distribution of fuel and air in the boiler to reduce emissions while improving combustion efficiency.

IMPROVE ENERGY EFFICIENCY THROUGH TIGHTER CONTROL

Evaporators

Since the evaporator products contain no more energy than the feed, all the heat that is applied to separate them is ultimately lost to the environment. Consequently, the more efficiently the process is operated, the greater the energy savings achieved.

IMPROVE ENERGY EFFICIENCY THROUGH TIGHTER CONTROL

Spray Dryers

The complex and energy intensive nature of the drying process creates significant energy savings opportunities by optimising control of this unit.

CONTACT SALES

Talk to an expert

Talk to an expert

Spiro Control reps aren’t just sales guys. Our team features extremely knowledgable people with experience in refining and chemicals who can help you formulate a custom solution for your company.

Schedule a meeting with a member of our team, give us a call at +44 1244 568 940, or chat with our team – whichever contact option you prefer, we’re here to help.

Spiro Control reps aren’t just sales guys. Our team features extremely knowledgable people with experience in refining and chemicals who can help you formulate a custom solution for your company.

Schedule a meeting with a member of our team, give us a call at +44 1244 568 940, or chat with our team – whichever contact option you prefer, we’re here to help.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

REAL RESULTS FROM CURRENT CUSTOMERS

Capacity increase (%)

Energy savings (%)

CO2 reduction (%)

Arkema deployed Spiro’s technology as part of our commitment to the Paris Climate Agreement. We achieved sufficient steam savings to decommission a site boiler. The project delivered significant benefits through reduced energy costs and CO2 emissions.

Jerome Berjouan

Process Control Specialist, Arkema

Solutions

Products & Services

Use Cases

News & Updates

Company

Contact