Digital technology for industrial sustainability and optimisation

Get deep insight into process performance and optimise your operations in real-time for lower emissions and improved operating margins.

Digital technology for industrial sustainability and optimisation

Get deep insight into process performance and optimise your operations in real-time for lower emissions and improved operating margins.

Capacity increase (%)

Energy savings (%)

CO2 reduction (%)

See how Spiro Control improves your plant

Built by people who know refining and chemical processing, Spiro Control provides the 21st century “smart plant” experience that manufacturers need to grow in a modern environment. See how it can help you drive revenue.

See how Spiro Control improves your plant

Built by people who know refining and chemical processing, Spiro Control provides the 21st century “smart plant” experience that manufacturers need to grow in a modern environment. See how it can help you drive revenue.

ARE YOU RUNNING BLIND?

“All of the problems we thought were small problems actually weren’t”.

Do your challenges include…

- Unexpected downtime?

- Regular flow of money down-the-drain due to underutilised equipment?

- Spending more time manually creating reports than really solving problems?

- Hitting daily or weekly production KPIs, and always feeling let down?

- Disappointed clients due to late deliveries or off-spec product?

- Lacking insight into composition of key streams?

- HYSYS model no longer aligned with your plant?

“All of the problems we thought were small problems actually weren’t”.

Do your challenges include…

- Unexpected downtime?

- Regular flow of money down-the-drain due to underutilised equipment?

- Spending more time manually creating reports than really solving problems?

- Hitting daily or weekly production KPIs, and always feeling let down?

- Disappointed clients due to late deliveries or off-spec product?

- Lacking insight into composition of key streams?

- HYSYS model no longer aligned with your plant?

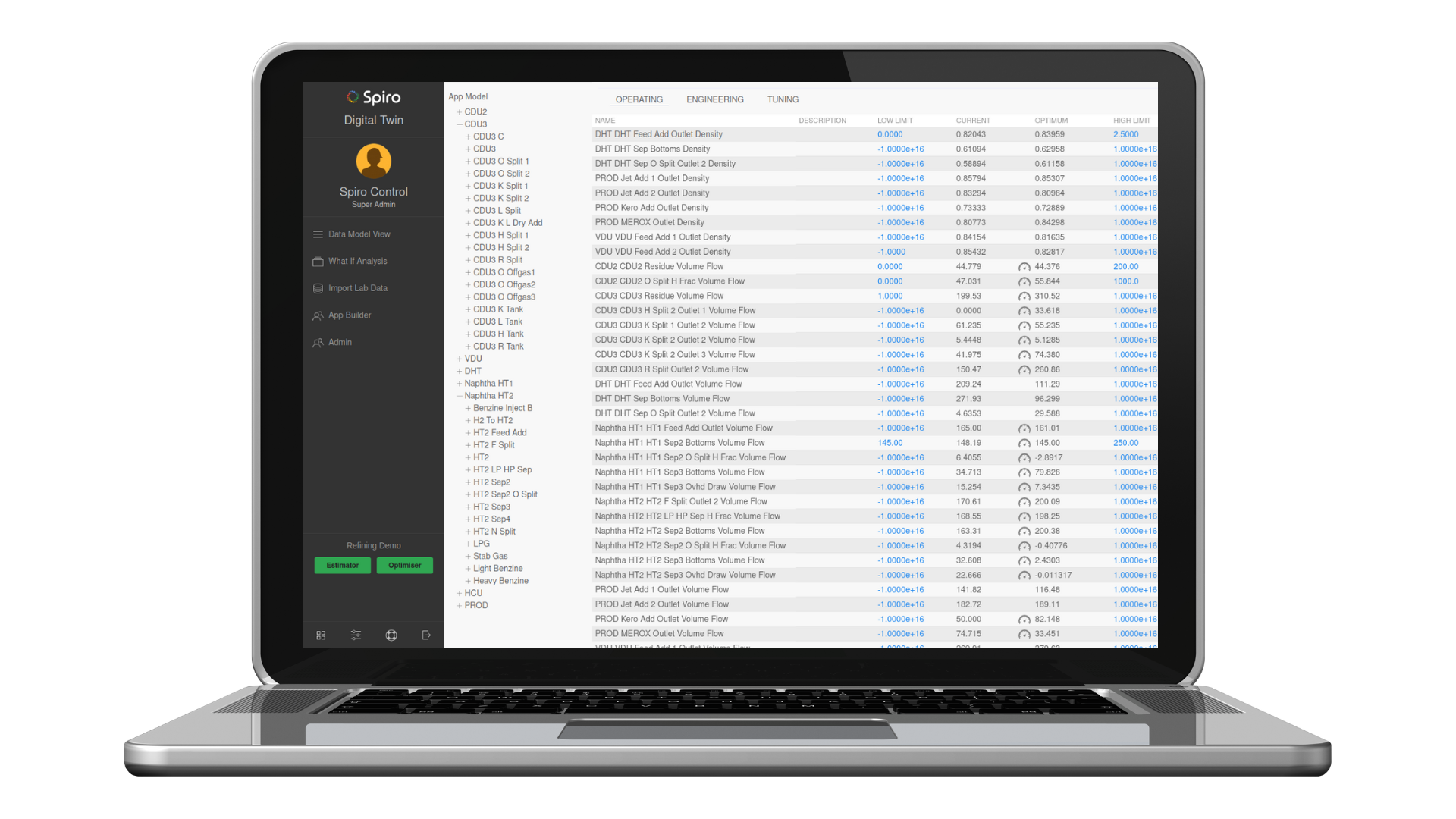

Process control tools that scales with your business

We match vast industrial control experience and knowledge of mathematics with a portfolio of process data analytics and real-time control and optimisation applications.

Process control tools that scales with your business

We match vast industrial control experience and knowledge of mathematics with a portfolio of process data analytics and real-time control and optimisation applications.

Expertise

- Our Principal Consultants each have over 30 years of industrial control experience

- We are technology ambidextrous, meaning we are able to work and integrate with many other applications and platforms

- Our developers have a range of backgrounds, from Chemical Engineering to Computer Science, to ensure we always develop useful solutions with industrial scalability

Leading technology

- Our Digital Twin and Optimisation applications run in real time

- Highly efficient MPC algorithms achieve millisecond execution frequency

- Intuitive web based UIs and on board dashboarding solutions

- All of our products categorised as IIoT / Industry 4.0 solutions

- AI / Machine learning used to “train” process models and decrease run time requirements

Agile methodology

- Continual communication with our clients, fostering collaboration

- Agile vs. Waterfall approach, meaning we can adapt to change requests and feedback throughout the project

- Early Application means we get feedback sooner, saving time and cost associated with lengthy iterations at the commissioning stage

Sustainability

As technology continues to evolve, Spiro Control is helping countless organisations embrace a data-driven culture. We are continuing to develop innovative products and processes that reduce carbon emissions, utilise fewer resources, and stay useful longer to ensure a cleaner, safer, greener future for all.

Industries

Industries

Renewable Energy

Chemicals

Energy

Petrochemicals

Food & Beverages

Pulp & Paper

Mining, Minerals & Metals

Natural Gas

NEXT STEPS

Upgrade your plant in three quick steps

Upgrade your plant in three quick steps

Real-time visibility

Understand what’s happening now.

Operational awareness

Make data driven adjustments on the fly.

Intuitive analytics

Continuously improve for long term growth.

CONTACT SALES

Talk to an expert

Talk to an expert

Spiro Control reps aren’t just sales guys. Our team features extremely knowledgable people with experience in refining and chemicals who can help you formulate a custom solution for your company.

Schedule a meeting with a member of our team, give us a call at +44 1244 568 940, or chat with our team – whichever contact option you prefer, we’re here to help.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Or schedule a live demo

Use the calendar below to schedule a meeting with a member of our team.

Solutions

Products & Services

Use Cases

News & Updates

Company

Contact